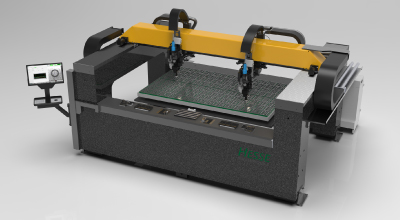

Laser Welder LW2095 – Fully automatic Laser Welding System

with two weldheads and an extra large working area

The Laser Welder LW2095 is a laser welding system for fully and semi-automatic deep penetration welding of aluminum and copper leads on DCB substrates, in power electronics, battery cells and modules, or other electronics manufacturing components.

Laser welding uses a laser beam to create intermetallic joints along a weld seam.

Both temporal and spatial laser power modulation enable different weld geometries and depths with the Laser Welder LW2095. A movable holding-down device avoids contamination of the surrounding area by weld pool ejections („splashes“) during the welding process

Constant precision throughout the manufacturing process is ensured by high axis accuracy and a professional process control, which ensures reproducibility of clamping force („zero-gap-challenge“) and welding conditions.

This standardized „clamp and weld“ concept offers fast adjustment to different product variants and flexible product change-over. It also makes it possible to react automatically to component tolerances of the joining partners to be welded.

Laser Welder LW2095

- Extra large working area: 2400 mm × 1400 mm × 45* mm (X×Y×Z)

- Fast welding times

- Different weld geometries and depths due to temporal and spatial laser power modulation

- Active vertical axis with sensor technology

- Sensor for touchdown detection in combination with an adjustable hold-down force avoids damage to sensitive contact partners

- Two weldheads with 1.5 kW laser beam source

- Image recognition (PR) for precise detection and correction of the weld location

- Minimal mechanical and thermal load

- Process monitoring via sensors for process illumination (plasma, thermal illumination and backscattered radiation)

- Standardized interfaces for line integration (e.g. OPC-UA, profinet)

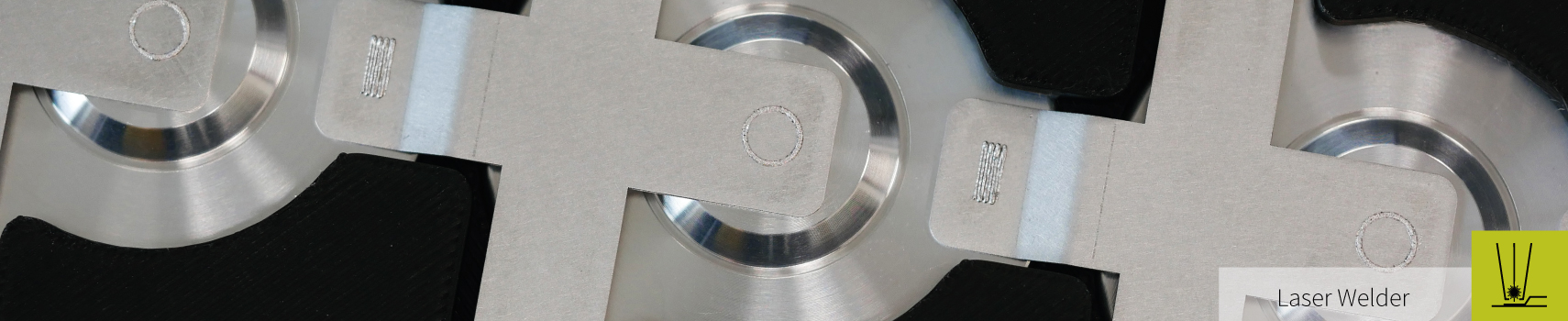

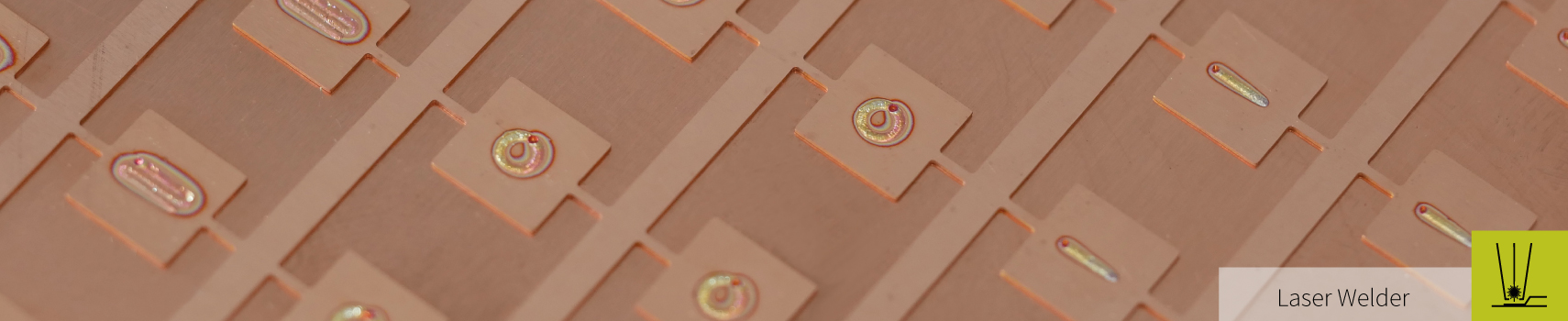

Application examples:

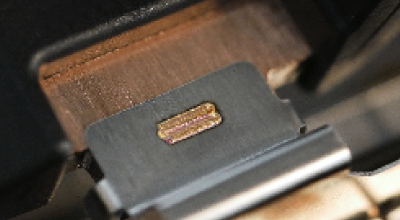

Laser welded application example

- Welding of Cu leads on DCB/AMB

- Welding of Cu leads on Cu Busbar

- Welding of battery cells

- Welding of Al leads on Al

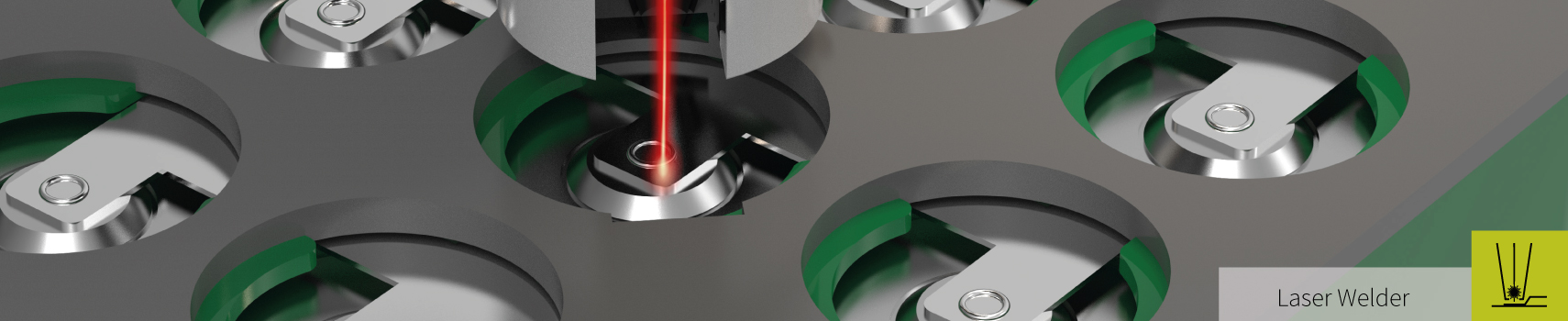

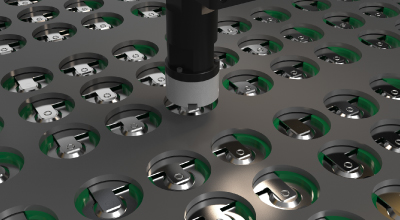

Laser weldhead

Laser Weldhead

- Down hold force up to 120 N

- Regulation of the down hold force

- Touchdown detection

- Max. immersion depth: 94 mm

- Monitoring optics with ring light and image recognition

- Exchangeable down hold device

- Process gas supply / ventilation at the welding spot

Beam source

- Max. power: 1.5 kW, cw

- Laser beam quality: Single Mode

- Wavelength: 1070 nm

- Optionally, the laser beam source can be equipped with an air-water cooler

for autarkic operation without a cooling water network

Optic

- Hesse optics module

- Focus spot diameter < 50 μm in combination with the above-mentioned laser

- Max. working area of the optics: 12 mm x 12 mm. Current achievable field of work results from the contour of the holding-down device

- Max. power: 1.3 kW, cw

- Permissible wavelength: 1070 nm

- Focus position dynamically adjustable

- Shape of the welded seam is configurable (line, wobble, spiral, circle, meanders;

customer-specific weld geometries can also be implemented - Temporal power modulation

- Process observation via backscattered radiation and / or process lights

- Dynamics of optics:

- Line welding with up to 1000 mm/s

- Wobble seam: Wobble frequency up to 1000 Hz

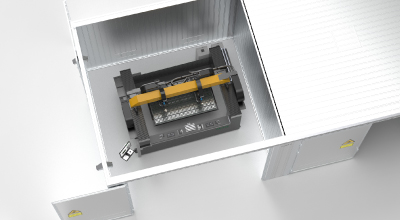

Housing*

Housing of Laser Welder LW2095

- The machine needs to be equipped with a protective housing and safety devices . The protective housing must be designed for the foreseeable maximum radiation and must also offer the required strength.

*(not in our equipment portfolio, please contact us for further information)

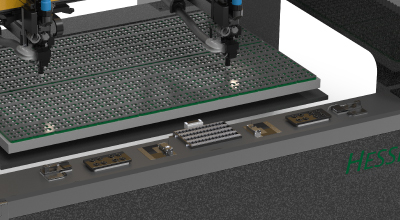

Service Stations

- Tool force calibration module

- E-Box station for laser beam alignment

- Tool changing station (as option)

- Integrated beam shape measurement and focus position

determination - Off-bond-station for welding samples

Service Stationen

Working area

| Laser Welder | X | Y | Z |

| LW2095 | 2400 mm | 1400 mm | 45** mm |

| P-rotation: 360° | |||

(**depending on product configuration)

Footprint

| W x D x H [mm] | |

| LW2095

excl. attached parts like e.g. control panel, status lamp |

4434 x 3000 x mind. 2460 |

| External switch cabinet

excl. attached parts like main switch, door handles |

1800 x 600 x 2200 |

| Laser switch cabinet

excl. attached parts like main switch, door handles |

600 x 600 x 2000 |

Download Brochure

Please complete the request form using the button and enter your name and business e-mail address. A download link will be sent to you after verification.

Software Options

For the growing demand of connectivity and industry 4.0

Automation

Standard components or individually adapted solutions

Article: Efficient Laser Welding Systems

Read the article “Efficient laser welding systems for battery module and electronics production” here

Hesse GmbH Headquarters

Hesse GmbH

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.