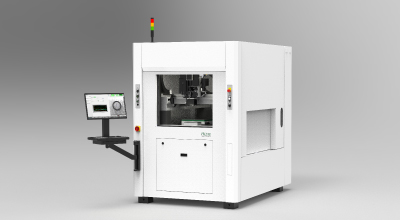

Fully automatic Laser Welding System

with a large working area

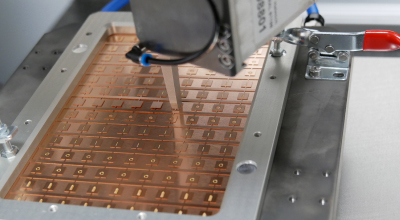

The Laser Welder LW1089 is a laser welding system for fully and semi-automatic deep penetration welding of aluminum and copper leads on DCB substrates, in power electronics, battery cells and modules, or other electronics manufacturing components. Laser welding uses a laser beam to create intermetallic joints along a weld seam.

Both temporal and spatial laser power modulation enable different weld geometries and depths with the Laser Welder LW1089. A movable holding-down device avoids contamination of the surrounding area by weld pool ejections („splashes“) during the welding process.

Constant precision throughout the manufacturing process is ensured by high axis accuracy and a professional process control, which ensures reproducibility of clamping force („zero-gap-challenge“) and welding conditions. This standardized „clamp and weld“ concept offers fast adjustment to different product variants and flexible product changeover. It also makes it possible to react automatically to component tolerances of the joining partners to be welded.

- Large working area: 410 mm × 480 mm × 75* mm (X×Y×Z)

Laser Welder LW1089

- Fast weldng times

- Different weld geometries and depths due to temporal and spatial laser power modulation

- Active vertical axis with sensor technology

- Sensor for touchdown detection in combination with an adjustable hold-down force avoids damage to sensitive contact partners

- 1.5 kW laser beam source

- Image recognition (PR) for precise detection and correction of the weld location

- Minimal mechanical and thermal load

- Process monitoring via sensors for process illumination (plasma, thermal illumination and backscattered radiation)

- Standardized interfaces for line integration

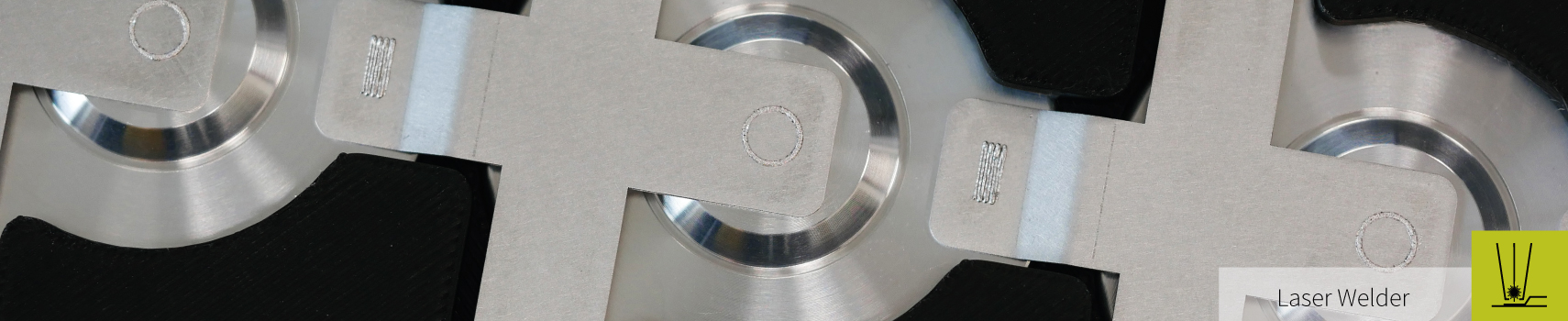

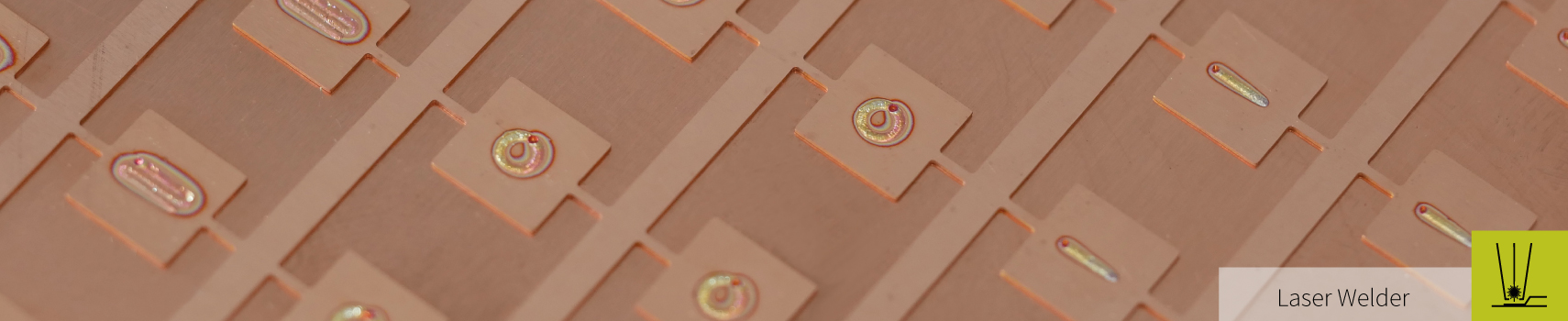

Application examples:

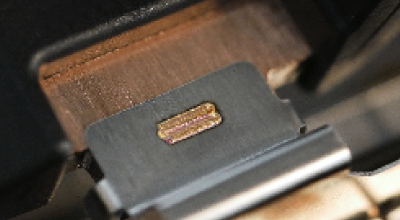

Laser welded application example

- Welding of Cu leads on DCB/AMB

- Welding of Cu leads on Cu Busbar

- Welding of battery cells

- Welding of Al leads on Al

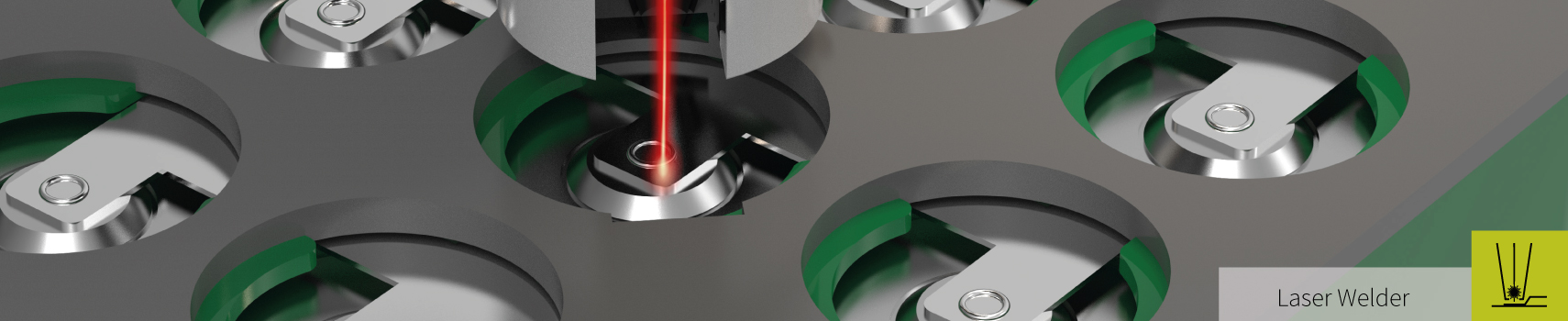

Laser Weldhead

Laser weldhead

- Down hold force up to 120 N

- Regulation of the down hold force

- Touchdown detection

- Max. immersion depth: 100 mm

- Monitoring optics with ring light and image recognition

- Exchangeable down hold device

- Process gas supply / ventilation at the welding spot

Beam source

- Max. power: 1.5 kW, cw

- Laser beam quality: Single Mode

- Wavelength: 1070 nm

- Optionally, the laser beam source can be equipped with an air-water cooler for autarkic operation without a cooling water network

Optic

- Hesse optics module

- Focus spot diameter < 50 μm in combination with the above-mentioned laser

- Max. working area of the optics: 12 mm x 12 mm. Current achievable field of work results from the contour of the holding-down device

- Max. power: 1.3 kW, cw

- Permissible wavelength: 1070 nm

- Focus position dynamically adjustable

- Shape of the welded seam is configurable (line, wobble, spiral, circle, meanders;

customer-specific weld geometries can also be implemented - Temporal power modulation

- Process observation via backscattered radiation and / or process lights

- Dynamics of optics:

- Line welding with up to 1000 mm/s

- Wobble seam: Wobble frequency up to 1000 Hz

Service stations

- Tool cleaning station (as option)

- Tool force calibration module

- E-Box station for laser beam alignment

- Tool changing station (as option)

- Integrated beam shape measurement and focus position determination

- Off-bond-station for welding samples

Working area

| Laser Welder | X | Y | Z |

| LW1089 | 410 mm | 480 mm | 75* mm |

| P-rotation: 360° | |||

Footprint

| W x D x H [mm] | |

| LW1089

excl. attached parts like e.g. control panel, status lamp |

1480 x 2150 x min. 2092 |

| External switch cabinet

excl. attached parts like main switch, door handles |

800 x 1000 x 2100 |

(*depending on product configuration)

Download Brochure

Please complete the request form using the button and enter your name and business e-mail address. A download link will be sent to you after verification.

Software Options

For the growing demand of connectivity and industry 4.0

Automation

Standard components or individually adapted solutions

Article about Laser Welding Systems

Read our article about “Efficient Laser Welding Systems”

Hesse GmbH Headquarters

Hesse GmbH

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.