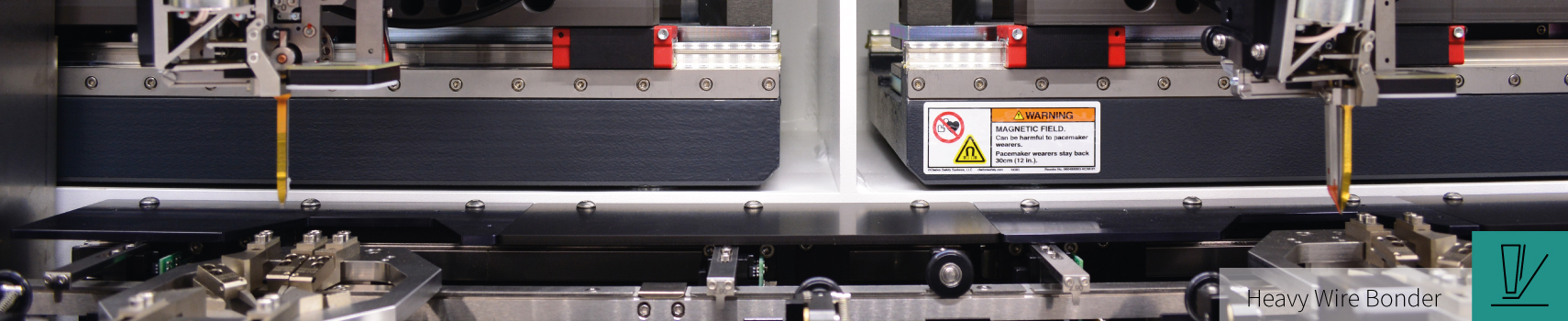

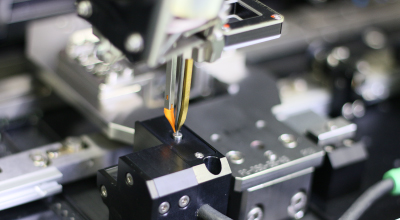

Bondjet BJ931 – fully automatic dual-head leadframe wedge bonder

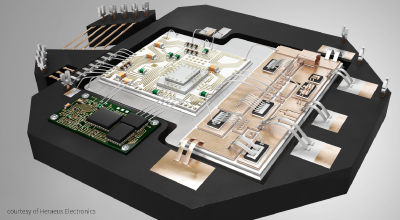

The Bondjet BJ931 is an ultrasonic wedge bonder developed especially for maxtrix leadframe applications. The application of two bondheads enables to bond two different wire sizes as well as a combination of wire and ribbon.

The fully automatic dual-head leadframe wedge bonder Bondjet BJ931 meets the latest technology and flexibility demands for automotive and power electronics applications; handling heavy aluminum, copper wire and ribbon on two specialized bondheads that can be exchanged.

Your benefits:

- Robust, clean design

- Low maintenance requirements

- User-friendly software

- Service support functions

- Industry-leading PiQC™ process monitoring system

- Precisely programmable bondforce actuator

- Wear-free components with Piezo technology

- Maintenance-free solid state joints

- Integrated, non destructive pulltest for wire and ribbon

- Automated bondforce calibration

- Pattern recognition time: 6 ms – 8 ms (search region: 512 × 512 pixels, pattern: 64 × 64 pixels)

- Rapid image capture with new digital image processing and flash light illumination

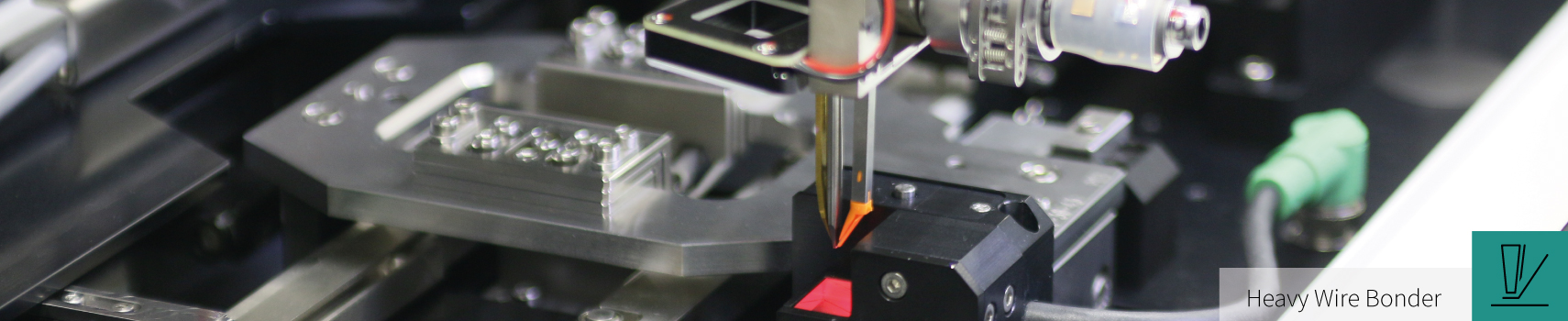

- E-Box: patented solution for optimized tool change and programmable alignment marks for cutter, wire guide and bond wedge

- Speed: Highest UPH due to linear motors for bonder and indexer

Central wedge bonder control system

- A central 23″ touch panel is used to monitor and control the bonder and indexing system

- Metal keypad and robust trackball for industrial use

- User-friendly calibration wizard and automatic update of calibration data at bondhead change on all available bondheads

Automotive Module

Quality

- Continuous, real time monitoring of wire deformation, transducer current and frequency within programmable control limits

- Process integrated Quality Control PiQC: detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); as option

- Remote pull function on PiQC threshold value for optimized cycle time; up to 30 % save on equipment

- Integrated, non destructive pulltest for wire and ribbon

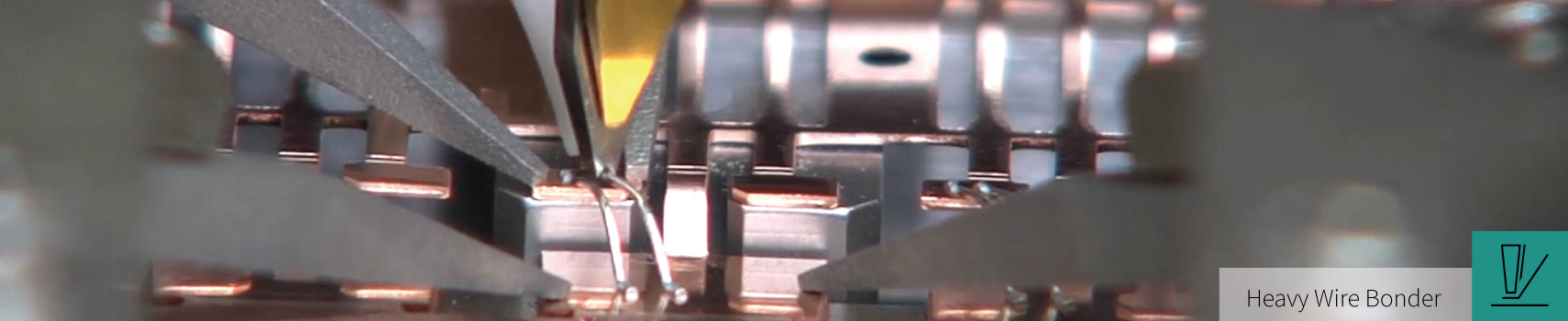

Mechatronic bonheads

E-Box

- Heavy wire and ribbon bondheads for Al, Cu and AlCu:

- HBK (Frontcut, Backcut); Frequency: 60 kHz*

- RBK Ribbon (Frontcut); Frequency: 57 kHz*

- RBK Copper (Frontcut, Backcut); Frequency: 57 kHz*

alternative frequencies available on request

- Cutting methods: active, passive, air cut (for frontcut)

- Digital ultrasonic generator with PLL (Phase Locked Loop),

internal frequency resolution <1 Hz; programmable ultrasonic power output - An intelligent bondhead connecting system with integrated memory stores all calibration data and enables bondhead replacement in a few minutes

- Wire clamp for loop shape control is standard on all bondheads;

optionally equipped with non destructive pulltest - Option: Inline pull modules: up to 4 modules per bondhead for a non-destructive pulltest (up to a total of 8 per system)

Wire

- Al, Cu, AlCu: 50 μm – 600 μm** (2 mil – 24 mil)

Ribbon

- Al, Cu, AlCu: 250 µm x 25 µm up to 2000 µm x 400 µm**

(Cu: 200 µm) (10 mil x 1 mil up to 80 mil x 16 mil)

Loop form functions

- Reproducible loop geometry by wire guide appropriate for the material involved and moving wire buffer

- Constant wire length and loop height

- Mechanically demanding loop geometrics by parameterization and individual wire clamp application

- Individual loop shapes by configurable loop trajectory generator

High speed leadframe indexer

- Strip dimensions :

100 mm – 280 mm length, 15 mm – 90 mm width,

max. 3.0 mm down-set - Substrate types: TO220, SOIC, SO8, SOL8, SOT, SOT23, SC70, power-QFN, QFN, DPAK, DFN, DSO, COB, multi-lead SOP, matrix L/F, flat-boat, programmable pitch etc.

- Index time: 100 ms for typical TO220 device (includes clamping)

- Magazine size: 115 mm – 285 mm length, 20 mm – 100 mm width,

50 mm – 200 mm height

Working area

| Bonder | X | Y | Z |

| BJ931 | 100 mm | 90 mm | 42 mm |

P-rotation: 440°

Footprint and weight

| Bonder | W x D x H [mm] | Weight |

| BJ931 | 1550 – 1725 x 1273 x 1885 | ca. 1400 kg |

| excl. attached parts like e.g. status lamp, control panel etc. | ||

Media connectivity

- Power supply 230V AC

- Gigabit-Ethernet (TCP/IP)

- USB-Ports

- HDMI

- Compressed air (CDA clean, dry air)

- Vacuum

* exact range of frequencies on request

**depending on application and wire

Download Brochure

Please complete the request form using the button and enter your name and business e-mail address. A download link will be sent to you after verification.

PiQC: Process integrated Quality Control

100 % Quality monitoring in real-time

Software Options

For the growing demand of connectivity and industry 4.0

Automation

Standard components or individually adapted solutions

Hesse GmbH Headquarters

Hesse GmbH

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.

Lise-Meitner-Str. 5

D-33104 Paderborn

+49 5251 1560-0

info@hesse-mechatronics.com

Copyright © Hesse GmbH – The Bonding Experts.