PiQC: Process integrated Quality Control

100 % Quality monitoring in real-time

Smart Welders combine the best of two technologies:

Smart Welding is the leading-edge technology in producing ultrasonically welded connections. This is due to increased process control, driving the limits of connecting different material combinations (e.g. for applications like power electronics and battery packs).

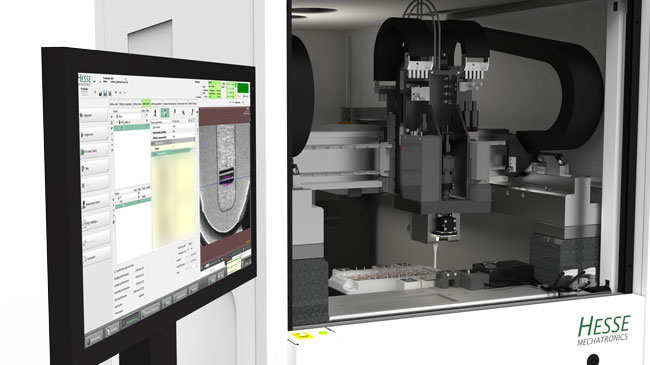

Smart Welders by Hesse, can precisely position a sonotrode to a product. An image recognition system determines the exact weld location very quickly and accurately, based on a derivation of an optimal trajectory. Together with long and narrow sonotrodes, this allows small pitching and compact products/higher power density.

Further advanced functions include touchdown sensing, precise and dynamic contact force control, diverse process control features such as monitoring of ultrasonic characteristics and deformation (ref. DVS 2811), and standardized interfaces for assembly line integration.

Smart Welders can, like ultrasonic wire bonders, flexibly handle a large variety of products. New products only require a program change and possibly adapted clamping and automation.

Rotational weldhead

Typical material specifications for aluminum and copper.

Other parameters as in the below mentioned overview are possible, but require prior individual clarification of data such as material, geometry, objective and other application specifics.

| Welding of … | Terminal | Pin/Rivet/Sleeve | |||

| Material | Thickness (Z) [mm] |

Area (X x Y)[mm2] |

Collar-Ø (d) [mm] |

Thickness (z)[mm] |

Length (l) [mm] |

| Cu | 0,2 – 1,2 | 1,0² – 3,5² | 1,5 – 2,5 | 0,1 – 0,5 | 3,0 – 18,0 |

| Al | 0,5 – 1,2 | 1,0² – 4,0² | – | – | – |

| Smart Welder | X | Y | Z |

| SW1089 – 400W | 392 mm | 870 mm | 50 mm |

| SW1089 – 1500W | 392 mm | 870 mm | 50 mm |

| Smart Welder | W x D x H [mm] | Weight |

| SW1089 | 930 x 1823 x 2040 | ca. 2100 kg |

| excl. attached parts like e.g. status lamp, control panel etc. | ||

| Welding of terminals, leadframes | Welding of pins and sleeves |

|---|---|

|

|

| Terminals on Power Moduls | Terminals on Battery Packs | Sleeves on DCB |

|---|---|---|

e.g. welding of | Cell contacting system for battery cells, battery modules and battery management system (BMS)

e.g. welding of

|

e.g. welding of |

Please complete the request form using the button and enter your name and business e-mail address. A download link will be sent to you after verification.

100 % Quality monitoring in real-time

For the growing demand of connectivity and industry 4.0

Standard components or individually adapted solutions